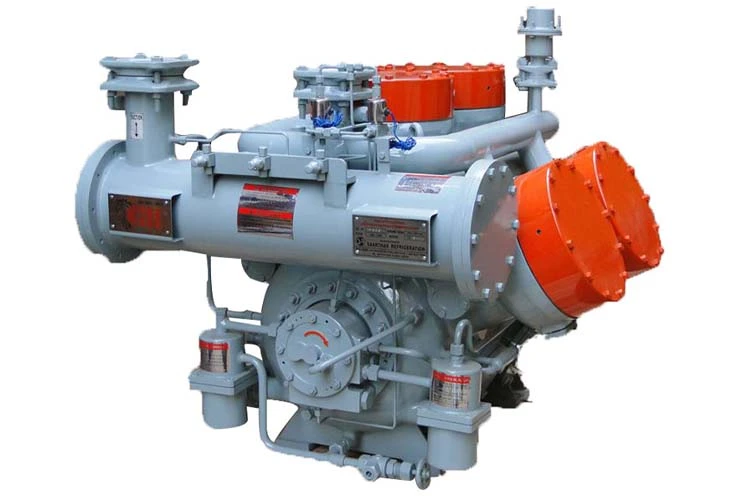

Ammonia Reciprocating Compressor

- Home »

- Ammonia Reciprocating Compressor

Buy Ammonia Reciprocating Compressor

Colt Ammonia Reciprocating Compressor is a type of compressor specifically designed for handling ammonia gas. It is commonly used in industrial refrigeration systems, cold storage facilities, and air conditioning units that require a reliable and efficient way to compress ammonia gas for various applications. The compressor works by drawing in ammonia gas, compressing it to a high pressure, and then transferring it to the condenser where it is cooled and liquefied. This process allows for the efficient circulation of ammonia as a refrigerant, making it a popular choice for many cooling systems due to its excellent heat transfer properties and low environmental impact.

Colt takes pride in being recognized as the leading manufacturer and supplier of Ammonia Reciprocating Compressors in Delhi, India. With a strong commitment to quality, innovation, and customer satisfaction, Colt has established itself as a trusted partner in the industry. Our compressors are designed to meet the demanding requirements of various applications, delivering reliable performance and efficiency. By leveraging cutting-edge technology and expertise, Colt ensures that our products meet the highest standards of excellence. Customers can rely on Colt for top-notch compressors that are built to last and deliver exceptional value.

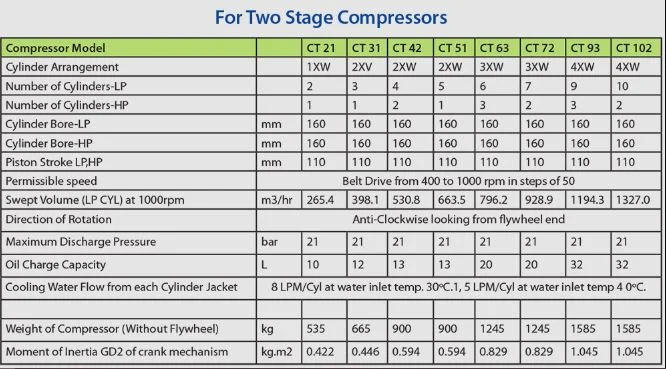

2, 3, 4, 6, 9 and 12 Cylinder Series the leading technology with displacement from106.16 to 1592.4 m3/h Applicable for : R22, NH3 (Ammonia)

Discharge Valve Assembly

- Three Concentric discharge valve rings ensure ample gas at flow passage at low lifting height ensuring a smaller number of breakdowns.

- The use of sinusoidal spring made of Sandvik Steel, Sweden together with precision machined and lapped surface result in a trouble -free operation for a remarkable long time.

- Minimum inventory for spares since most parts are identical throughout the CT-Series Compressors.

Cylinder Liner

- Interchangeable cylinder liners are made of fine-grained, centrifugally cast, alloy iron.

- Fine boring and honing results in a mirror smooth running surface.

Suction Valve

- A hydro-mechanical suction valve lifting mechanism on each individual cylinder achieves loading and unloading.

- For unloading, the suction valve ring is lifted from its seat in the cylinder collar by spring tension. Admitting controlled oil pressure to the control piston, allows the suction valve ring to descend on its seat effects loading of the cylinder.

Easy Cleaning

- Suction gas strainer is another example of easy maintenance. Inside gauze strainer element can be easily removed.

Lubrication System & Filter

- Forced lubrication by a gear pump, driven directly by the crankshaft.

- The pump incorporates a differential pressure regulator to provide separate pressures for two oil systems: lubrication system and control oil system (Loading and Unloading).

- Automatically operating hydraulic delay valve ensures complete unloaded start.

- A metal gauze suction filter element and a throwaway discharge paper filter cartridges are provided for excellent filtering capacity of the lubricating oil with rare earth magnet ensure trouble free long running life.

- Oil return flow is visible with built-in Sight Glass.

Crankshaft

- Bearing surfaces of the high-quality nodular cast iron crankshaft are ground to fine tolerances.

- Each crankshaft is dynamically balanced together with the counter weights resulting in smooth vibration free running.

Main Bearings

- Main bearings are white metal lined steel backed bushes, pressed into the cast iron bearing covers. Intermediate bearing blocks are provided with spit type bearing shell of the same type.

Safety Pressure Spring

- Is ensured by built-in arrangement of buffer spring which protects compressor from incidental liquid hammer.

Easy & Quick Maintenance

- As piston/connecting rod assembly can be removed without removing the cylinder liner.

- Parts subjected to wear are easily accessible through large service doors with minimum special tools.

- Large water jacket around the cylinder with flange type covers are provided for easy cleaning and descaling avoids gas cutting and acid cleaning.

- Service covers are large in size.

- Gas tightness and impact proof.

- Smooth internal surfaces and chemical cleaning process guarantee the good oil condition during operation.

Piston

- Perfect sealing and low oil consumption due to 3 compression and 2-oil scrapper rings on each aluminium alloy piston thus minimizing oil carryover through discharge gas line.

Connecting Rod Assembly

- The forged steel connecting rod is drilled through for pressure lubrication of the piston pin.

- Steel backed white metal shells on big end and Needle Roller Bearing on small end of connecting rod.

- The complete piston & connecting rod assembly can be removed from the top for servicing without withdrawing the cylinder liner which makes it easy for maintenance.

Welded Steel Crankcase

- Rapid heat dissipation

- Gas tightness and impact proof

- Smooth internal surfaces with chemical cleaning process guarantee the good oil condition.

Quality adaptable to varying operating conditions

- Each cylinder is equipped with a hydraulically operated valve lifting mechanism giving absolutely capable capacity control and 100% unloading.

Painting

- With special epoxy primer and Polyurethane (PU) paint preceded by shot blasting and chemical treatment process ensure long life & corrosion protection. Powder coating is optional if demanded.

Electrical Panel

- Ensure safe running of the compressor

- Maximum safety with failure detection LEDs display.

- Pressure gauges and cut-outs are secured in metallic panel.

- Toggle switch for operation of solenoid valve.

- Hour meter used as a reference for running time of compressor for regular maintenance.

- Aesthetically attractive operation panel

Head Cooling*

- To keep the discharge temperature low.

- To increase the life of compressors.

* Only Head Cool Versions